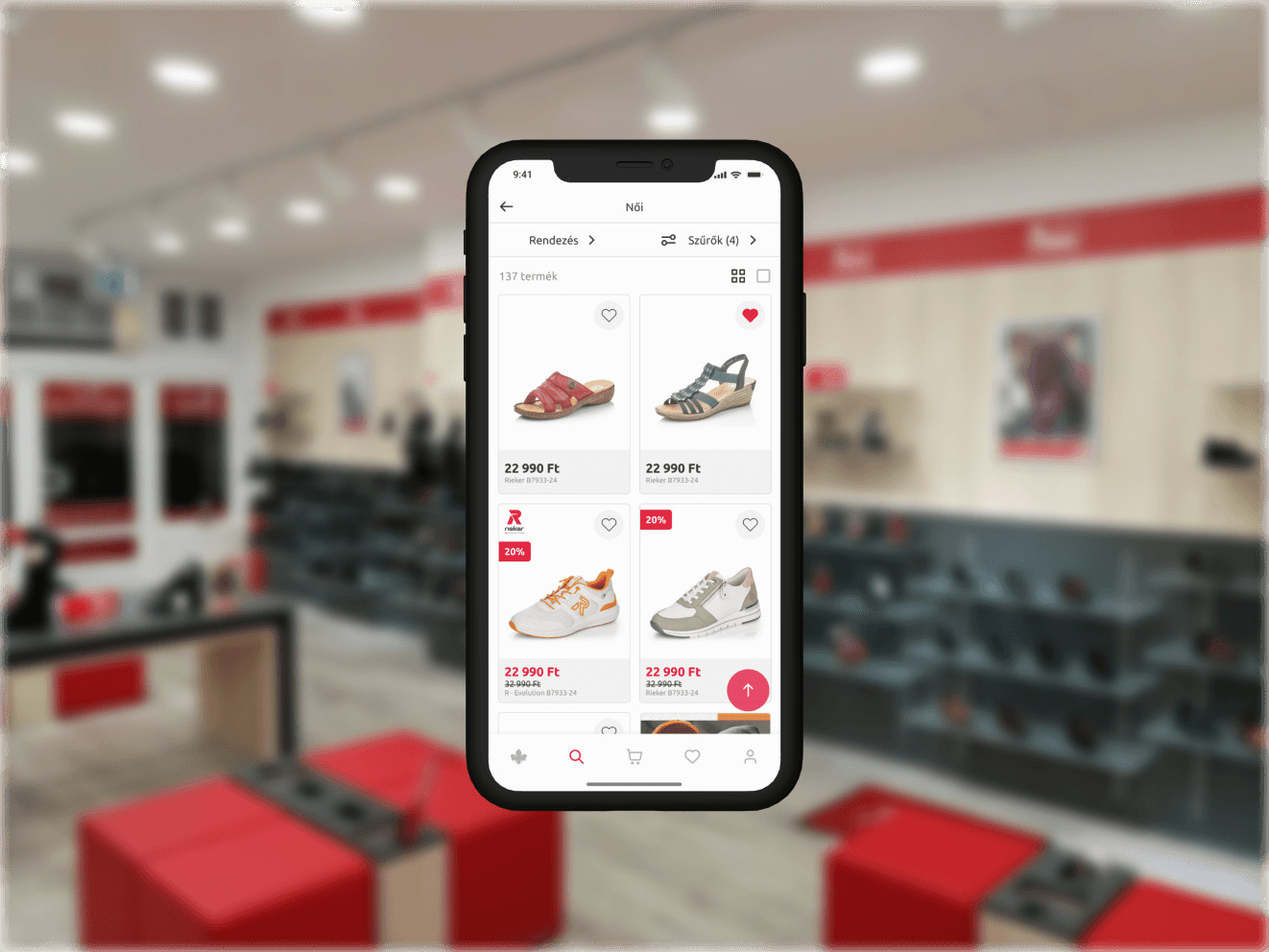

Inventory control application

Industry

Logistics

Team setup

1 developer + 1 designer

Timeline

2 weeks

Problem to solve

At the rieker-eshop.hu warehouse there are usually 60 000+ products. 4-5x a year the warehouse operators do a full inventory control, when they scan each and every product. The problem was that the processing of scans took around 3-4 seconds each, which made the work slow, inefficient and exhausting.

Challenge

Because of the high volume, usually there are extra temporal operators in the warehouse who have never used the system before - they must be able to work without training and mistakes.

Outcome

We built an easy-to-use, optimized inventory control application that processes the scans under 200ms. With this the time needed for a full inventory control dramatically reduced.

Inventory control application

Industry

Logistics

Team setup

1 developer + 1 designer

Timeline

2 weeks

Problem to solve

At the rieker-eshop.hu warehouse there are usually 60 000+ products. 4-5x a year the warehouse operators do a full inventory control, when they scan each and every product. The problem was that the processing of scans took around 3-4 seconds each, which made the work slow, inefficient and exhausting.

Challenge

Because of the high volume, usually there are extra temporal operators in the warehouse who have never used the system before - they must be able to work without training and mistakes.

Outcome

We built an easy-to-use, optimized inventory control application that processes the scans under 200ms. With this the time needed for a full inventory control dramatically reduced.

Inventory control application

Industry

Logistics

Team setup

1 developer + 1 designer

Timeline

2 weeks

Problem to solve

At the rieker-eshop.hu warehouse there are usually 60 000+ products. 4-5x a year the warehouse operators do a full inventory control, when they scan each and every product. The problem was that the processing of scans took around 3-4 seconds each, which made the work slow, inefficient and exhausting.

Challenge

Because of the high volume, usually there are extra temporal operators in the warehouse who have never used the system before - they must be able to work without training and mistakes.

Outcome

We built an easy-to-use, optimized inventory control application that processes the scans under 200ms. With this the time needed for a full inventory control dramatically reduced.

Inventory control application

Industry

Logistics

Team setup

1 developer + 1 designer

Timeline

2 weeks

Problem to solve

At the rieker-eshop.hu warehouse there are usually 60 000+ products. 4-5x a year the warehouse operators do a full inventory control, when they scan each and every product. The problem was that the processing of scans took around 3-4 seconds each, which made the work slow, inefficient and exhausting.

Challenge

Because of the high volume, usually there are extra temporal operators in the warehouse who have never used the system before - they must be able to work without training and mistakes.

Outcome

We built an easy-to-use, optimized inventory control application that processes the scans under 200ms. With this the time needed for a full inventory control dramatically reduced.

Browse more of our successes

Find more of our successes and learn about our processes!

Browse more of our successes

Find more of our successes and learn about our processes!

Browse more of our successes

Find more of our successes and learn about our processes!

Browse more of our successes

Find more of our successes and learn about our processes!